Summary

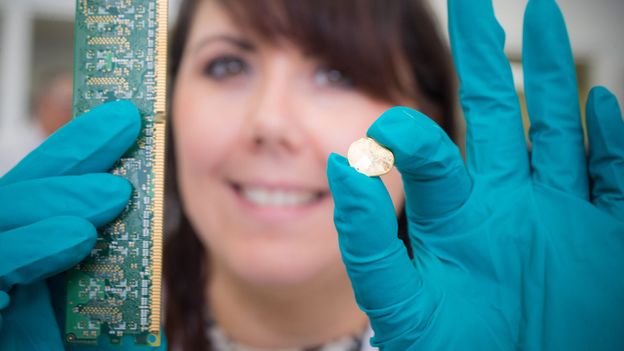

The UK Royal Mint has developed an innovative method to extract precious metals, particularly gold, from electronic waste such as discarded laptops and mobile phones. This sustainable and energy-efficient process claims to recover 99% of gold from printed circuit boards, and the Royal Mint plans to open a factory capable of processing 90 tonnes of circuit boards per week, potentially recovering hundreds of kilograms of gold annually. The method involves a chemical solution that dissolves and leaches gold at room temperature and is “environmentally friendly”, producing fewer greenhouse gas emissions than traditional smelting methods. The initiative aims to reduce e-waste and the environmental impact of mining for raw materials.

Other Details

-

E-waste is a rapidly growing waste stream, with an estimated 50 million tonnes produced globally each year.

-

Only 20% of e-waste is formally recycled, with the rest often sent to landfill or incinerated.

-

The Royal Mint’s initiative is focused on sustainable recycling within the UK and reducing the need to export e-waste for processing.

-

The method has the potential to recover other precious metals like palladium, silver, and copper.

-

The goal is to establish a network of local e-waste suppliers and processors to encourage reuse and reduce waste miles.

-

The Royal Mint aims to generate 70% of its required power from renewables, including energy produced from the waste processing.

-

There is growing interest in recycling e-waste to recover valuable materials and reduce the environmental impact of mining for these resources. Innovative methods like this could drive the growth of a more circular economy for precious metals.

Also, they’re saying they will recover “hundreds of kilos” (let’s call that two hundred!) from… 4.68 million kilos of circuit board!

Where’s the rest of it going?!?

Asia usually.